In 2024, we had the pleasure of sitting down with one of Europe’s leading vegetable growers, Agromačaj A.S., based in Slovakia to discuss their experiences using the ARA ultra-high precision sprayer. Managing over 12,000 hectares, including 750 dedicated to onions, Agromačaj A.S. is one of the largest producers of onions in Europe. They shared how adopting the ARA has transformed their farming operations, from improving crop health to supporting environmental sustainability. Here’s what they had to say:

First Interests in the ARA Sprayer

The journey began with a visit to Ecorobotix in Switzerland. Intrigued by the potential of ultra-high precision spraying, the farmers were drawn to the ARA’s promise of being “gentle to the onion itself.” As leaders in cultivating onions, carrots, potatoes, and seed corn across 27 crops, they saw ARA as a critical investment in their operations.

“We had high expectations,” Agromačaj A. S’s Head Agronomist of Onions, Luboslav Vavcercak, explained. “Even in the early test versions, we could see the difference between treated and untreated areas.”

Following a successful introduction, they initially purchased two ARA sprayers, which quickly became indispensable tools. Running 24/7 during peak periods, the sprayers complete a full cycle across their onion fields every five days. They bought a third ARA this winter and now have three machines ready for the new season.

Real-World Challenges and Adaptations

Adopting cutting-edge technology comes with a learning curve. During early trials, the carrot algorithm required fine-tuning to achieve peak efficiency. Issues and occasional weather-related challenges also arose. However, the growers praised Ecorobotix’s responsive support team, noting their dedication to quickly resolving issues.

“Even in windy conditions and high-density fields, the ARA delivers consistent results,” Agromačaj A. S’s Mechanization and Precision Farming Specialist, Ivan Farago, shared.

The team is already looking forward to expanding the ARA’s use to soybean and seed corn fields, as well as addressing volunteer potatoes, a persistent challenge in their operations.

Impressive Results: Precision and Sustainability

The impact of the ARA on their crops has been transformative. The ultra-high precision sprayer has drastically reduced herbicide use, cutting application from 200 liters to just 28.2 liters per hectare, a remarkable 86% savings in first year. These reductions contribute to healthier soils, fewer chemical residues, and crops that meet the strictest supermarket and EU standards.

“We’ve almost eliminated the use of fungicides,” Vavcercak remarked. “The reduced chemical stress leads to healthier onions and larger yields, even under challenging weather conditions.”

Vavcercak and Farago also highlighted visible growth advantages in ARA-treated fields compared to untreated areas, showcasing the sprayer's precision and effectiveness.

Future Outlook: Technology Leading the Way

Looking ahead, Agromačaj A.S. envisions a future dominated by AI and robotics in agriculture.

“With fewer individuals entering farming, technologies like the ARA sprayer are essential to addressing labor shortages while improving efficiency and sustainability,” shared Farago.

The growers are already exploring robotic systems for planting and weeding, reaffirming their belief that technology is the key to modernizing agriculture.

A Partnership Built on Precision and Trust

Reflecting on their experience, the farmers expressed their satisfaction with the ARA sprayer and their collaboration with Ecorobotix. The ARA has become an integral part of their mission to enhance efficiency and sustainability while meeting the challenges of large-scale farming.

“It’s the best when there are no weeds,” Farago joked. “But even when the conditions are tough, the ARA proves its worth.”

This Slovakian grower’s story illustrates how precision technology can revolutionize agriculture, combining efficiency, sustainability, and crop health. As they continue to innovate and expand their use of the ARA sprayer, their experience sets a benchmark for modern farming across Europe and beyond.

European Success and U.S. Expansion

Marchetti explained that ARA has been successfully operating in Europe for over five years, with hundreds of units deployed. The sprayer’s effectiveness has fueled its expansion into North America, where it is now supported by Ecorobotix’s U.S. subsidiary, currently in Pasco, Washington. Initial adopters have already seen strong returns, with some customers ordering additional units after just one season.

Key Benefits: Labor Reduction, Cost Savings, and Yield Improvements

The ARA sprayer is transforming agricultural operations with its ultra-high precision capabilities. By leveraging advanced AI and 156 individual nozzles, ARA targets weeds with an unparalleled 2.4-inch (6x6 cm) accuracy, reducing overspray and ensuring that only necessary areas receive treatment.

One of the most immediate advantages is labor reduction. ARA’s targeted application allows farmers to complete spraying tasks in fewer passes and with less manual weeding, optimizing efficiency and cutting down on operational costs. Farmers have also reported chemical input reductions of up to 95%, contributing to both economic and environmental sustainability.

Beyond cost savings, ARA also delivers notable yield improvements. By eliminating unnecessary herbicide application and minimizing stress on crops, the sprayer promotes healthier plants. Farmers using ARA have seen yield increases of 3-7%, with some crops benefiting even more due to earlier harvesting opportunities. In high-value crops such as onions, even small yield gains translate into substantial profit margins.

Tackling Drift and Adapting to U.S. Conditions

Another standout feature of ARA is its ability to minimize spray drift, a critical issue for U.S. farmers, particularly in windy regions like the Pacific Northwest (Now certified to reduce drift by 95%!). Unlike conventional boom sprayers, ARA’s precise targeting ensures chemicals reach only the intended plants, reducing drift and maximizing efficiency.

A Transformative Future for Precision Agriculture

With a full schedule of orders for 2025 and increasing interest from farmers across the country, ARA is poised to redefine precision spraying in the U.S. By merging cutting-edge AI technology with practical field applications, Ecorobotix continues to drive sustainable and profitable solutions for modern agriculture.

For the full interview, visit The Onion Podcast at: (READ) (LISTEN)

Ecorobotix has been awarded the 2024 Avantgarde Award by the Swiss-American Chamber of Commerce (Swiss AmCham) Southern California. This honor celebrates our dedication to advancing Swiss-American business relations through forward-looking innovation and impactful contributions to sustainable agriculture. After placing as a finalist last year, we are incredibly proud to have achieved first place in 2024.

The Avantgarde Award acknowledges the achievements of businesses, non-profits, and individuals who foster strong, innovative, and mutually beneficial connections between Switzerland and the United States. Ecorobotix was recognized for its contributions to cutting-edge agricultural technology, our commitment to environmental stewardship, and the positive impact we’ve generated within the industry.

The rigorous selection process for this award includes evaluations by a distinguished jury composed of experts from Switzerland and the U.S., representing industry, academia, and government. This year, the jury included representatives from institutions such as the University of Southern California (USC) and ETH Zurich, who assessed submissions based on criteria like technological innovation, economic performance, job creation, and commitment to diversity, equity, and inclusion. The three finalists included Ecorobotix, HILTI, and Georg Fischer (GF).

Our CBO, Claude Juriens, was honored to represent Ecorobotix at the Avantgarde Gala on November 8 at the California Club in Los Angeles, where our achievements in sustainability and circular economy practices were celebrated among distinguished peers and business leaders.

This recognition reinforces our commitment to fostering sustainable, impactful innovation that benefits both our customers and the broader Swiss-American business community. We extend our deepest gratitude to the Swiss-American Chamber of Commerce, the jury, and all those who continue to support our journey.

At Ecorobotix, we are dedicated to delivering cutting-edge precision spraying technology that empowers farmers to significantly reduce herbicide usage. Data from nearly 3,000 missions in onion fields using our ARA ultra-high precision sprayer reveals impressive results, with nearly 70% of all missions achieving herbicide savings of 80%, and some missions saving as much as 98%.

This graph shows the herbicide savings. Each dot represents a unique ARA sprayer mission, with the x-axis showing randomized onion missions and the y-axis indicating the percentage of herbicide savings, ranging from 0% to 100%.

One of the key takeaways is the consistency of these savings. Most missions demonstrate herbicide savings between 60% and 98%, with a significant concentration around the 80% mark (results depend on factors such as weed density and target type, including monocot and dicot weeds).

This data, collected from ARA sprayers deployed globally, highlights the machine’s ability to adapt to diverse field conditions.

By focusing only on the weeds and avoiding unnecessary spraying on healthy crops, ARA helps farmers reduce herbicide waste, minimizing both environmental impact and crop damage. As more farmers adopt precision agriculture, the advantages of using the ARA sprayer become even more evident. These substantial savings not only lower input costs but also contribute to more sustainable farming practices, making agriculture more eco-friendly across the globe.

Article Summary

Introduction:

It is estimated that weeds are responsible for 34% of crop losses. Therefore, weed control is the greatest challenge in agriculture to ensure food security while maintaining high health and nutritional standards. The ARA precision field sprayer from Ecorobotix (Fig. 1 A) is an efficient solution for chemical weed control. ARA uses artificial intelligence and highly precise, localized spraying technology (Fig. 1 B) to effectively combat weeds while achieving higher yields. The study compares different weed control methods: an untreated control (NT), ARA with selective products, ARA with non-selective products, and broadcast spraying.

Results:

- In 2023, the ARA field sprayer saved over 78.9% of herbicide quantities in weed control for onion crops over 1 hectare compared to traditional broadcast treatments.

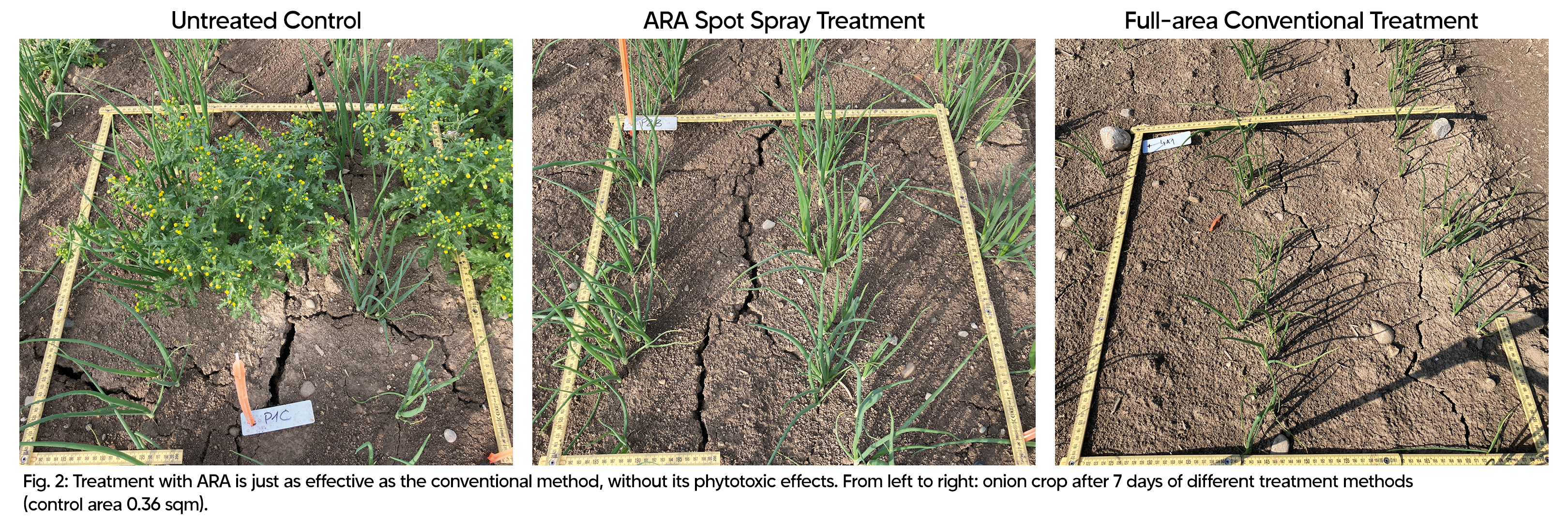

- ARA showed a global weed elimination efficacy of 92% compared to 99% for the broadcast treatment, with fewer applications (5 with ARA compared to 9 conventional) and simultaneously preserving the integrity of the crops (Fig.2).

- Weed control with ARA ensures higher yields per hectare (67 t/ha) compared to conventional application (43 t/ha) and untreated control (59 t/ha).

Summary:

In summary, ARA significantly contributes to environmental protection by drastically reducing the use of plant protection products in crops. By eliminating weeds and reducing the phytotoxic effects of chemical weed control agents, the potential of crops is maximized.

Download the entire study here

Preliminary Results

The team noted a clear growth defect on the onions sprayed with the conventional sprayer, the onions are considerably smaller than the onions in the plots treated with ARA. Overall crop health with the ARA sprayer seems much higher than with the conventional spraying method, even when increasing the dosages of the herbicides used.

Further testing will be completed, and conclusive results are to be published towards the end of the season.

More articles about onions : > types-of-crops/onion/

The onion algorithm by Ecorobitx has been on the market as a fully functional product for 2 years. It’s being used by a number of farmers across Europe, mainly in Italy, France, and Switzerland of course.

This demonstration was organised on the Egger & Sons estate in Chavornay (Switzerland). We used ARA to spray a selective herbicide targeting weeds such as broadleaf and grassy weeds. Up to 7.5 km/h, weeds are successfully detected by the camera and sprayed by the machine.

Video of the test run

Efficient detection system

The visual recognition system detects weeds, whatever their development stage. In the video, you can see that weeds are identified even at a very early stage: just after germination, when they’re still at the seedling stage, they're recognised by the typical shape of the cotyledons and the two first leaves.

What you can also see in this video is that no weed is ignored. Even more, no onion bulb is wrongly identified as a weed.

Our algorithm also detects weeds when they are located close to or even on the onion plant. The mix of shapes and colours doesn't trump our visual recognition system.

Ultra-high precision spraying

Being able to spray up to an accuracy of 6 x 6 cm, ARA can treat even the weeds that are very close to the onion bulbs without affecting them.

Since ARA only sprays what needs to be sprayed and nothing else, it uses a lot less plant protection product. On onion crops, the decrease in product usage is around 70% to 80%.

«With ARA, even a non-selective plant protection product becomes selective, because it’s sprayed in an ultra-targeted way, only where it needs to be.»

Loïc Wüthrich, technical sales engineer at Ecorobotix

For all seasons and soils

The onion algorithm is one of the most comprehensive and versatile of the Ecorobotix product range. The first reason is that there are spring and summer onion varieties and they will fight different weeds depending on the season. So we had to train the visual recognition system to identify all these various weeds, at every development stage.

Also, onion can be grown on many different kinds of soils. In the Orbe plain in Switzerland, onion is grown in very dark and peaty soils. In Loiret (France) however, our partner Groupe Méthivier has run a number of tests on lighter-coloured, mineral soils. In the Rhine plains, some farms have very diverse terrain, where you can switch from black soil in some areas to lighter tones a few yards away. So we had to train our algorithm to work on various soils so it can be efficient on all farms.

The demanding tests we run with our team have shown that our detection models are robust. They work fine, whatever the season or the colour of the soil.

ARA’s efficiency in cornfields: the numbers

- 46 litres of plant protection blend by hectare

- Detection rate: 95%

- Treatment rate: 95%

- Ecorobotix tested its ultra-high precision ARA sprayer, based on artificial intelligence, on an onion plot in Loiret, in collaboration with La Coopérative Beauce Champagne Oignon (BCO).

- Tests show promising results, with a reduction of up to 93% in the TFI (Phytosanitary Treatment Frequency Indicator).

Yverdon-les-Bains, Switzerland, 31st January 2022. This autumn, Ecorobotix, a start-up offering ultra-high precision farming solutions tested its ARA smart towed sprayer on an onion crop plot in Loiret (France). The results are promising and allow the volume of product used to be reduced, compared to a conventional weed control solution.

Promising results: a precise and economical technology

The test was carried out by La Coopérative BCO and the Loiret Chamber of Agriculture, as part of the Club Oignon Régional Centre Val de Loire, with financial assistance from the Centre-Val de Loire region.

Two treatment sessions spaced apart by seven days were carried out and have helped to highlight the following:

- The precision and effectiveness of ARA in targeting plants, measured by using methylene blue on the crop. Ecorobotix’s technology makes it possible, thanks to its integrated artificial vision, to classify the plants and to adjust watering by ultra-short jets up to an accuracy of 8x3cm.

- The effective reduction of 93% in the TFI (Phytosanitary Treatments Frequency Indicator) compared to the volume of product used with a conventional weeding technique on another section of the plot.

Therefore, the ARA sprayer offers producers and farmers many advantages over other types of weed control processes: a decrease in the quantity of chemical products used, a high reduction of residue and phytotoxicity on crops and fewer losses.

"I voluntarily accepted the proposal to test a new method, which allowed me to reduce the use of phytosanitary products. The subject is of utmost importance for our business since, logically, the TFIs determine whether the High Environmental Value certification and other seals of approval can be achieved. The test is conclusive regarding this aspect and we await to see the next production and the impact on the yield obtained, as the control of products can only have a beneficial effect on the quality of the harvest. We want to continue the experiment on other larger crops."

Damien Jamet, farmer member of La Coopérative BCO.

Links

Visuals of the test with BCO can be downloaded from this link

Official photos of ARA by can be downloaded via this link

Press release in PDF : Link

About La Coopérative B.C.O

La Coopérative Beauce Champagne Oignon (B.C.O) specialises in producing, packaging and commercialising onions, garlic, shallots and echalion shallots. It brings together 55 producers/members over a surface area of 650 hectares, spread across three production areas: the regions of Centre-Val de Loire (Loiret), Île-de-France and Grand Est (Champagne/Ardennes).

In order to meet the expectations of its clients in terms of products, the new Semaises site, opened in 2018, brings together the most advanced technologies in Europe. Optical sorters and infrared cameras to study onions bulb-by-bulb and to determine the most appropriate use for consumption. A 100% automated flow management.

Therefore, B.C.O relies on its 50 years of experience in production and is a major player in the agro-ecological transition in this sector: preserving soils, restoring biodiversity, plant health and reducing synthetic inputs.

Today, La Coopérative B.C.O has 45 employees, produces 30,000 tons of onions a year and has a storage capacity of 10,000 tons for a long-term supply.

Press Contact

Isabelle Aeschlimann

Communication officer Ecorobotix

media@ecorobotix.com